Ready to upgrade your screen print shop to an auto? It’s an incredible feeling to outgrow your current space, but a little daunting to be making a leap to automation. While you’re looking at presses to invest in, take a look around your shop, too. There are probably some tasks you could do while you’re weighing your automatic press options. Here’s a checklist to help you get started.

EQUIPMENT & SUPPLIES

Let’s start with the big stuff: equipment. A bigger press means higher output, larger screens, and potentially more of those large screens to reclaim. It’s likely you’ll need to invest in a larger conveyor dryer. A 10-color press that’s moving quickly will produce far more shirts per minute than a single manual printer. You’ll need both a longer chamber and a wider belt to be able to keep up with shirts cured per minute.

You’ll be able to lay 2 shirts side-by-side going down the conveyor belt (minimum of 36” wide), increasing your number of t-shirts cured by linear foot. The wider the belt, the more t-shirts you can cure at a time. You’ll also run the belt speed faster, running more shirts through while maintaining optimal dwell time. Without a large conveyor dryer, you’ll be backlogged at the conveyor, waiting for enough room on the belt to place more shirts.

Automatic presses use larger screens: 23”x31”. Using larger screens means exposing larger screens (duh). A large exposure unit is another piece of equipment printers will need at least a 23x31 exposure unit with a vacuum before the automatic press arrives at their doorsteps. An LED exposure unit will create the best stencil and can cut down on exposure times, too.

Do you still have an infrared flash unit? For most automatic press users, buying a quartz flash dryer with the automatic press is the optimal solution. Quartz flashes offer several benefits over infrared units. They only turn on when the sensor notices the platens move, and only stays on as long as you set. This helps printers to not burn platens and save electricity. Another benefit: the quartz bulbs flash ink faster than an infrared unit will. Because of this, quartz flashes are standard in the automatic screen printing industry and are well worth the extra investment.

Depending on the size of the automatic press you’re looking at, you may need more than one flash. Six-color presses operate great with one flash but presses larger than that benefit from having more than one flash unit.

Once shirts have been cured and the job is done, you’ll still need to reclaim them. Until you upgrade to a sweet automatic reclaimer, you’ll be reclaiming screens by hand. A washout booth is a must-have; the bigger the better. A 72” washout booth can handle multiple automatic-sized screens at a time. Depending on your current washout booth setup, this can make an impact on reclaim speed. A pressure washer and filtration system are a must-have in automatic shops. It all helps keep your time and costs down.

SUPPLIES TO UPGRADE

You’ve invested in bigger and better equipment. Now it’s time to tackle the supplies. As mentioned earlier, automatic screens are larger than standard manual screens. Get an arsenal of 23”x31” screens to use day after day on your automatic press.

Pro Tip: Depending on the manual press you work with, invest in automatic screens and start using them now. By using one size of the screen in your whole shop, you’ll make screen creation, registration, and cleanup a lot faster, since you won’t need to adjust for different sizes of screens.

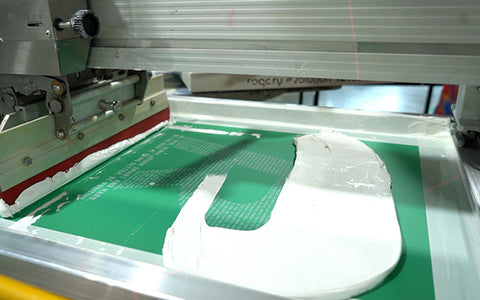

Another supply you’ll need is squeegee blades of different durometers. It’s always handy to have a stack of squeegee blades to replace old blades on current squeegees or on your future auto press. If you don’t invest in another set of squeegee holders — the piece of equipment that holds the squeegee rubber — for the auto press, you’ll be switching out squeegee blades pretty often. Get a set of blades for the types of designs and ink systems you use.

RELATED: HOW TO CHOOSE THE PROPER SQUEEGEE BLADE DUROMETER

One more thing: stock up on ink. The goal when going auto is to increase output, right? Buying gallons of white ink at a time might not be the most cost-effective way to buy ink. By purchasing large containers like 5 gallons, you’ll be saving money and stress by running out of ink less frequently. Expect to graduate one container size up when buying commonly-used inks. For example, buy white & black inks in 5-gallon containers and colors of ink in gallons.

Pro Tip: On average, when you add ink to a screen on an automatic press, you’re adding a minimum of 500 grams and up to 1000 grams of ink for each screen. That’s about half a quart to a full quart of ink on each screen, just to run a job.

RELATED: INTERESTED IN AN AUTOMATIC PRESS? HERE ARE 3 FACTORS TO CONSIDER

ARTWORK

While using your manual press, did you compensate in your artwork because your press struggled to hold registration? Did you engineer big traps or overlapped colors to cover the press moving? With an auto, you should be going with butt registration and slimmer traps for your base white.

When engineering artwork for automatic printing, you’ll need to consider the quantity and placement of flash units available. While automatic presses can flash every color using multiprint mode — and sometimes you’ll need to utilize this feature — it shouldn’t be the norm. Learning wet-on-wet basics and incorporating them into your daily print routine will help your shop run at top speed.

Pro Tip: As a new auto-user, understand that not all art can be printed wet-on-wet. Blocky, bold colors or colors that need to remain as pristine as possible shouldn’t be printed wet-on-wet. When a design can’t be printed wet-on-wet, utilizing multiprint to get the job done will be beneficial. As you become more technically savvy and obtain better tools, the designs that you might shy away from will become more and more possible.

RELATED: WHY PRINTERS NEED TO MASTER ADOBE ILLUSTRATOR FOR SCREEN PRINTING

SHOP SPACE

You’ve tackled the equipment and supply investment. First up: footprint. Does the space in your shop accommodate the automatic press you want?

No matter the size of the automatic press you choose, it’ll have a large footprint. Even small autos take up more space than a large manual like the Riley Hopkins 300. So if you’re printing on a large manual press and feeling a little claustrophobic, you’ll need to look for a bigger space before you go auto.

Every printer dreams of having the biggest and best automatic screen printing machine. The constant productivity, the influx of cash, the sight of your hard-earned money working hard for you. But if you have a smaller space, you might not be able to install that 10-color press you’ve been eyeing. And that’s okay. Increasing your shop’s output is a process.

Got a good-sized space? Next, look at the power requirements that your press and shop will need. Depending on the type of automatic press you invest in, you’ll need an air compressor and increased power requirements. Start by researching air compressors and have an electrician — or two — come to your shop and check for proper power and outlets.

Conveyor dryers should also be ducted, especially if they’re gas dryers. Start prepping your space with the proper ducting for the conveyor. Decide where you’ll place the press, conveyors, and other equipment. Then, contact an HVAC company to install the proper ducting so your shop stays safe and cool.

There’s one major component to all this: shipping and delivery. You’ll need to arrange the proper equipment to unload the new screen printing equipment and check the delivery schedule. Rent a forklift and pallet jack to get the press off the delivery truck and into your shop. If you’re not forklift certified, hire someone to help you.

Once the press is on the ground, it needs to be taken into your shop. Clear pathways large enough for the press to fit through, and verify that the press can fit through the doors in your shop.

All that’s left to do is install the press, get some training, and start cranking out shirts.

WILL YOU NEED HELP?

Auto shops can be run solo, but a lot of times it’s nice to have someone to help keep the workload manageable. But hiring an employee isn’t for everyone. So should you go it solo or get assistance?

First, ask yourself why you’re interested in an automatic in the first place. Is it because you’re turning jobs away, not having the time or press capability to handle them? Do you already have an employee — or five — and your team is still struggling to meet demand? Or are you considering going auto because it’s overall less expensive to make payments on a machine that doesn’t take sick days rather than pay an employee?

If you’re struggling to find enough hours in the day, going auto might be the solution. You’ll still need to do all the screen prep and reclaim, but you’ll be able to balance your time a little better while the automatic is printing. Loading and unloading shirts is a lot easier than pulling a squeegee for hours yourself.

The extra help can be used in tons of different ways at your shop. They could work on screen prep and reclaim, or help print jobs so you can focus on the business side of things. If you’d rather be the one working at the press, hire a business manager to take care of the paperwork.

A big part of the hiring process includes finding someone who’s a good fit for your shop. Hiring your friends can work, but doesn’t always come with quality. Sure, your friend Jeremy might have been your closest buddy since 3rd grade, but does he have a good work ethic? It can be hard to hire (and fire) friends.

No matter whether you choose to hire an employee or stay solo, upgrading to an automatic press is a big step and will take your shop to the next level.

RELATED: SHOULD YOU GO AUTO OR HIRE ANOTHER PRINTER?

Start checking off these tasks, and you’ll be ready for an automatic press in no time. Buy an auto that works for you, and have the extra equipment ready so you can get straight to learning on the job.